15 min read

Product Guide

Checklist

Sealant Selection for Chilean Climate Conditions

Chile's diverse climate zones require specific sealant types for optimal performance. From coastal humidity to mountain temperature swings, choosing the right product ensures long-term weather protection. Understanding chemical compositions and performance characteristics helps select appropriate solutions.

100% silicone sealants offer superior flexibility and UV resistance for exterior applications. They perform excellently in coastal areas where salt air accelerates material degradation. Acrylic sealants provide paintable surfaces for interior applications and areas requiring aesthetic matching. Polyurethane sealants offer superior adhesion for demanding exterior applications.

High-performance hybrid sealants combine the best properties of multiple chemistries for challenging applications. These products handle extreme temperature variations common in Chile's interior valleys while maintaining long-term flexibility and adhesion. Professional-grade products provide extended warranties and superior performance ratings.

Chilean building codes may require specific performance ratings for fire safety or environmental reasons. Always verify product compliance with local requirements before selection and installation.

12 min read

Installation Guide

Quick Fix

Joint Sealing: Flashing and Skylight Protection

Proper joint sealing prevents water penetration at building transitions where different materials meet. Chilean homes face unique challenges with thermal expansion and seismic activity that require flexible, durable sealing solutions. Understanding joint types helps select appropriate techniques and materials.

Expansion joints accommodate building movement while maintaining waterproof integrity. These joints require flexible sealants that can stretch and compress without losing adhesion. Control joints provide planned separation points that prevent random cracking. Construction joints occur where new work meets existing construction and require specific preparation and sealing techniques.

Proper surface preparation ensures optimal sealant performance. Clean, dry surfaces with appropriate priming improve adhesion and longevity. Backer rods control joint depth while providing support for sealant application. Tooling creates smooth, watertight joints that shed water effectively.

Technical Note: Proper joint design considers expected movement, thermal expansion rates, and chemical compatibility between sealants and substrates. Professional consultation ensures optimal long-term performance.

10 min read

Technology Review

Quick Fix

2024 Sealant Technology: Latest Advances

Recent advances in sealant technology provide enhanced performance for challenging Chilean climate conditions. New polymer chemistries offer improved flexibility, adhesion, and longevity. Understanding these advances helps select cutting-edge solutions for demanding applications.

Advanced hybrid polymers combine silicone flexibility with polyurethane adhesion for superior all-around performance. These products handle extreme temperature variations while providing excellent UV resistance and weathering characteristics. New moisture-cure formulations provide faster curing in humid conditions common in coastal Chile.

UV-resistant formulations prevent yellowing and maintain structural integrity under intense solar exposure common in northern Chile. Anti-microbial additives resist mold and bacterial growth in humid environments. Self-leveling formulations simplify application while ensuring complete joint filling and protection.

Environmentally conscious formulations reduce VOC emissions while maintaining performance standards. These products meet strict environmental regulations while providing professional-grade performance for residential applications.

11 min read

Specialized Application

Seasonal

Skylight Sealing: Complex Penetration Protection

Skylights create complex penetrations requiring specialized sealing techniques to prevent water infiltration. Chilean homes with skylights face additional challenges from thermal expansion and UV exposure. Proper sealing ensures long-term performance while maintaining energy efficiency.

Skylight perimeter sealing requires flexible materials that accommodate thermal movement while maintaining waterproof integrity. Flashing integration creates multiple barriers against water penetration. Proper slope and drainage around skylights prevent water accumulation that can lead to leaks and structural damage.

Interior condensation management requires proper ventilation and moisture barriers. Chilean climate variations create complex moisture movement patterns that require comprehensive approach to skylight sealing and condensation control. Professional installation ensures optimal performance and warranty compliance.

Energy efficiency considerations include thermal breaks and appropriate sealing materials that minimize heat transfer while providing superior weather protection. Quality skylight sealing reduces energy costs while preventing moisture problems.

14 min read

Professional Techniques

Checklist

Professional Application Techniques and Tools

Proper application technique ensures optimal sealant performance and longevity. Chilean contractors use specialized tools and methods developed for local conditions and building types. Understanding professional techniques helps achieve superior results with DIY applications.

Surface preparation creates optimal bonding conditions including cleaning, priming, and joint design. Proper joint dimensions ensure adequate sealant thickness while preventing excessive material usage. Backer rod installation controls depth while providing support for proper tooling and adhesion.

Application tools include caulking guns with proper thrust ratios for different viscosity products. Putty knives and specialized tooling tools create smooth, professional finishes. Proper application speed and angle ensure complete joint filling without air entrapment or material waste.

Quality control includes proper curing conditions, timing, and inspection procedures. Environmental factors including temperature, humidity, and substrate conditions affect curing and performance. Professional application ensures manufacturer warranty compliance and optimal long-term performance.

8 min read

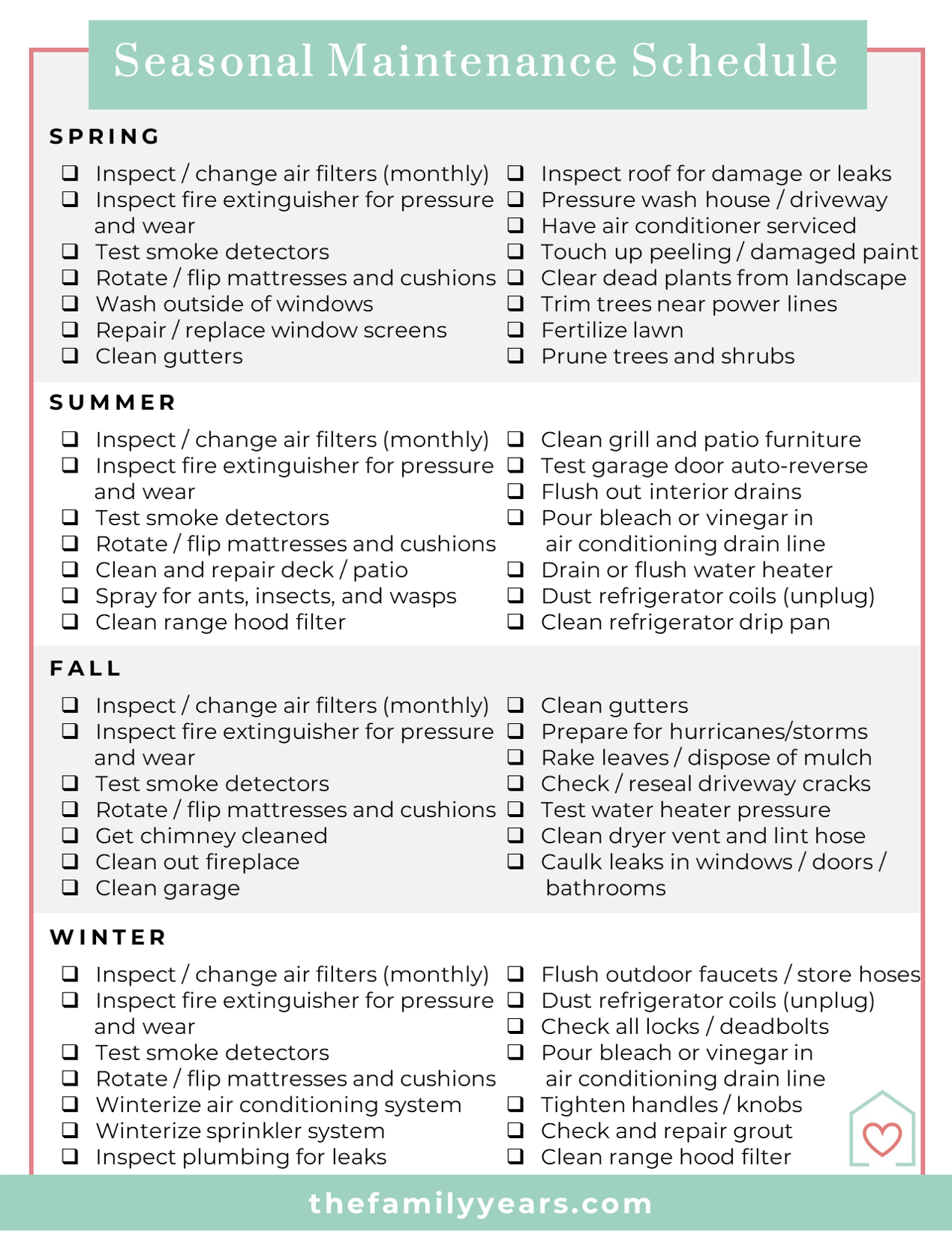

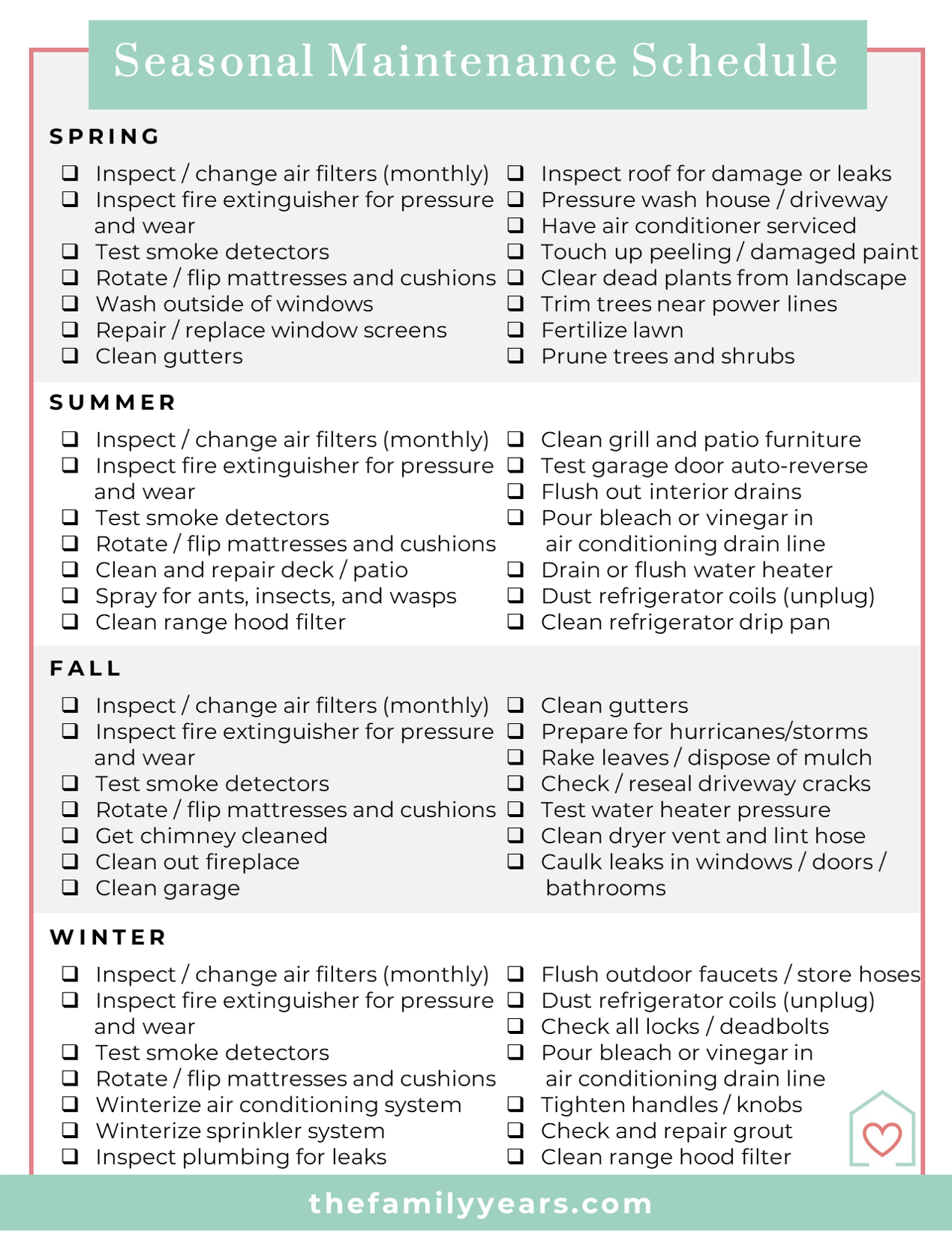

Maintenance Schedule

Seasonal

Sealant Maintenance and Inspection Scheduling

Regular inspection and maintenance extends sealant life while preventing costly water damage. Chilean climate conditions affect sealant aging differently in various regions, requiring specialized maintenance schedules. Proactive maintenance prevents small problems from becoming major repairs.

Seasonal inspection schedules account for Chile's weather patterns and building movement cycles. Pre-storm inspection identifies vulnerable areas requiring attention before severe weather arrives. Post-storm assessment detects damage from extreme weather events requiring immediate repair.

Visual inspection techniques identify early signs of degradation including cracking, separation, and discoloration. Structural movement indicators help predict maintenance needs before failures occur. Documentation of maintenance activities helps track performance and plan future needs.

Chilean building codes may specify minimum inspection and maintenance requirements for commercial buildings and certain residential applications. Professional consultation ensures compliance while optimizing maintenance schedules for specific conditions.

9 min read

Technical Guide

Checklist

Chemical Compatibility and Substrate Testing

Chemical compatibility between sealants and substrates affects long-term performance and durability. Chilean construction materials vary significantly, requiring compatibility testing for optimal results. Understanding chemical interactions prevents premature failure and ensures warranty compliance.

Substrate compatibility testing identifies potential problems with adhesion, staining, or chemical reactions. Common substrates include concrete, wood, metal, glass, and various plastics used in Chilean construction. Each requires specific preparation and compatible sealant types for optimal performance.

Environmental compatibility considers temperature extremes, UV exposure, and chemical exposure common in Chilean climate zones. Coastal areas require salt spray resistance while mountain areas need freeze-thaw cycle performance. Desert regions require UV stability and dust resistance.

Compatibility testing procedures include small test applications and observation periods before full installation. Professional application often includes warranty coverage for compatibility issues when proper procedures are followed.

6 min read

Emergency Response

Quick Fix

Emergency Waterproofing: Storm Damage Response

Storm damage often requires immediate waterproofing to prevent secondary damage while permanent repairs are arranged. Emergency techniques provide temporary protection using readily available materials and simple application methods. Quick response prevents small problems from becoming major repairs.

Temporary patching with roofing cement, plastic sheeting, or specialized emergency sealants provides immediate leak protection. These materials bond to most surfaces and provide temporary weather protection until permanent repairs can be made. Interior protection includes plastic sheeting and containers to collect dripping water.

Emergency joint sealing uses caulking gun application of appropriate sealants for immediate protection. Surface preparation includes cleaning debris and loose material for optimal temporary adhesion. Documentation of damage and repair efforts aids insurance claims and professional repair planning.

Safety Note: Emergency repairs during storms require careful attention to safety conditions. Never attempt repairs during active storms or on wet surfaces. Use appropriate protection and avoid electrical hazards.

7 min read

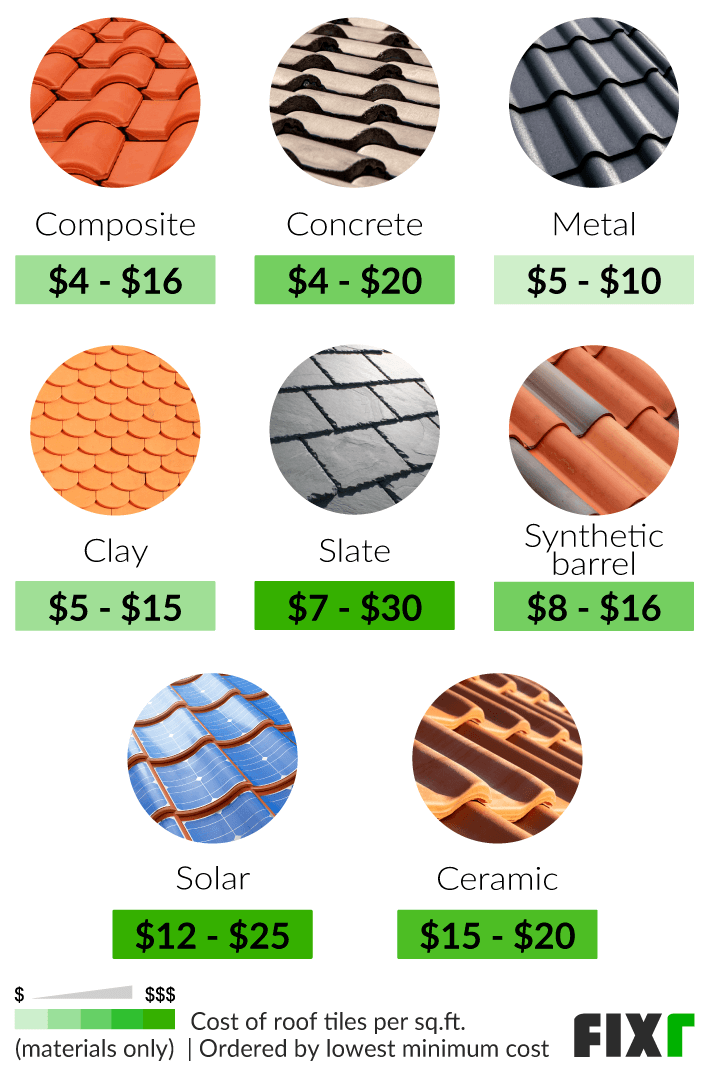

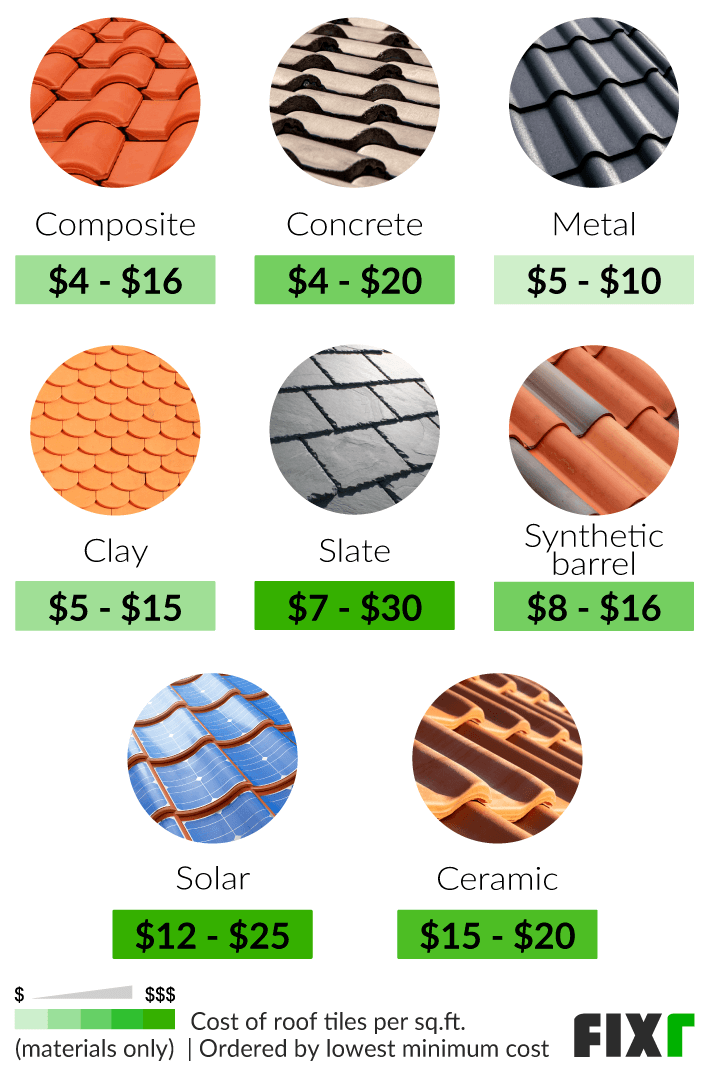

Cost Analysis

Checklist

Sealant Cost-Effectiveness: Investment Protection

Understanding sealant costs helps optimize protection investments while preventing expensive water damage. Chilean homeowners face various cost considerations including material prices, application costs, and potential damage expenses. Cost-effectiveness analysis ensures optimal value for protection investments.

Material costs vary significantly by performance level and chemistry type. Professional-grade sealants cost more but provide superior performance and longevity that reduces long-term maintenance costs. Economy products may seem cost-effective initially but require more frequent replacement and maintenance.

Application costs include professional labor and DIY time investment. Quality application ensures optimal performance and warranty compliance while reducing maintenance requirements. Proper application prevents premature failure that can exceed material cost savings.

Damage costs from inadequate waterproofing include structural repairs, interior damage, mold remediation, and foundation problems. These costs often exceed sealant investment by significant margins, making quality waterproofing cost-effective protection.